Get This Report about Sheroz Earthworks

Get This Report about Sheroz Earthworks

Blog Article

The smart Trick of Sheroz Earthworks That Nobody is Talking About

Table of ContentsSheroz Earthworks - The FactsFascination About Sheroz EarthworksThe Best Strategy To Use For Sheroz Earthworks4 Easy Facts About Sheroz Earthworks DescribedThe Best Guide To Sheroz Earthworks

For any kind of earthwork specialist, it is essential to perform job with high quality, accuracy, and on timetable. Using machine control in work machines allows enhancing the various stages in the earthwork process, from intending to the upkeep stage - fj dynamics autosteer review. The maker control system aids the maker driver in attaining the target airplane swiftly and quickly

The maker control system overviews the operator with centimeter accuracy. Remote assistance saves time and money, as it decreases downtime in jobsites.

6 Simple Techniques For Sheroz Earthworks

Our system's elements are carefully made to stand up to the harsh problems of building and construction sites. Comparison of the very same job carried out making use of device control versus the standard method discloses that, on average, the typical technique calls for 50% even more time to achieve the exact same task as the technology-assisted method.

Enter the Xsite device control system; it's right here to offer you with a significant benefit when functioning with earthmoving machinery. Discover how Xsite Equipment Control can enhance your performance and guarantee work safety and security! Xsite Maker Control systems can be mounted to any kind of excavator from mini excavators to huge mining excavators.

Exactly how does equipment control work? In 2D systems, the device is outfitted with adjusted disposition sensors. These sensing units are installed on the pre-determined parts of the equipment in excavators the sensing unit are generally installed to the structure, boom (or booms), miner arm and to the fast coupler - trimble tripod parts. By making use of the data received from these sensors the system can calculate the specific placement of the excavators container pointer in significance to a reference factor.

The system is really simple to learn the essentials can be taught in under one hour of training. How does the remote support work? A cordless internet link makes it possible to establish a remote connection between the device control system and the solution.

The Basic Principles Of Sheroz Earthworks

Xsite Equipment Control systems sustain open common data layouts, making it possible for smooth details circulation from one system to an additional. Depending on your option of system (with or without placing, i.e., 2D or 3D), your device is geared up with inclination sensors, a controller system, and a display/operating panel.

Several software and hardware services exist to aid establish a machine's present setting on the earth and contrast it with a desired layout surfaceand construction drivers can do even more to utilize the benefits. Equipment control is making use of different positioning sensing units and a screen to supply the driver with a recommendation between the setting of the container or blade and the target grade.

Depending upon the configuration, equipment control systems can give the driver with a basic visual guide to bucket or blade placement, or can immediately move the blade to grade by speaking to the device's hydraulics - https://www.storeboard.com/sherozearthworks. There are machine control systems offered for simply about any type of machine: , dozers, excavators, soil and asphalt compactors, scrapes, leaners, milling devices, and pavers

Fascination About Sheroz Earthworks

Some benefits consist of lowered rework, enhanced task effectiveness, and reduced surveying prices. Maker control can likewise help increase efficiency and decrease overall costs. This innovation is altering the way the building industry works. Construction devices without machine control will certainly end up being a point of the past and the benefits gained from it will be various.

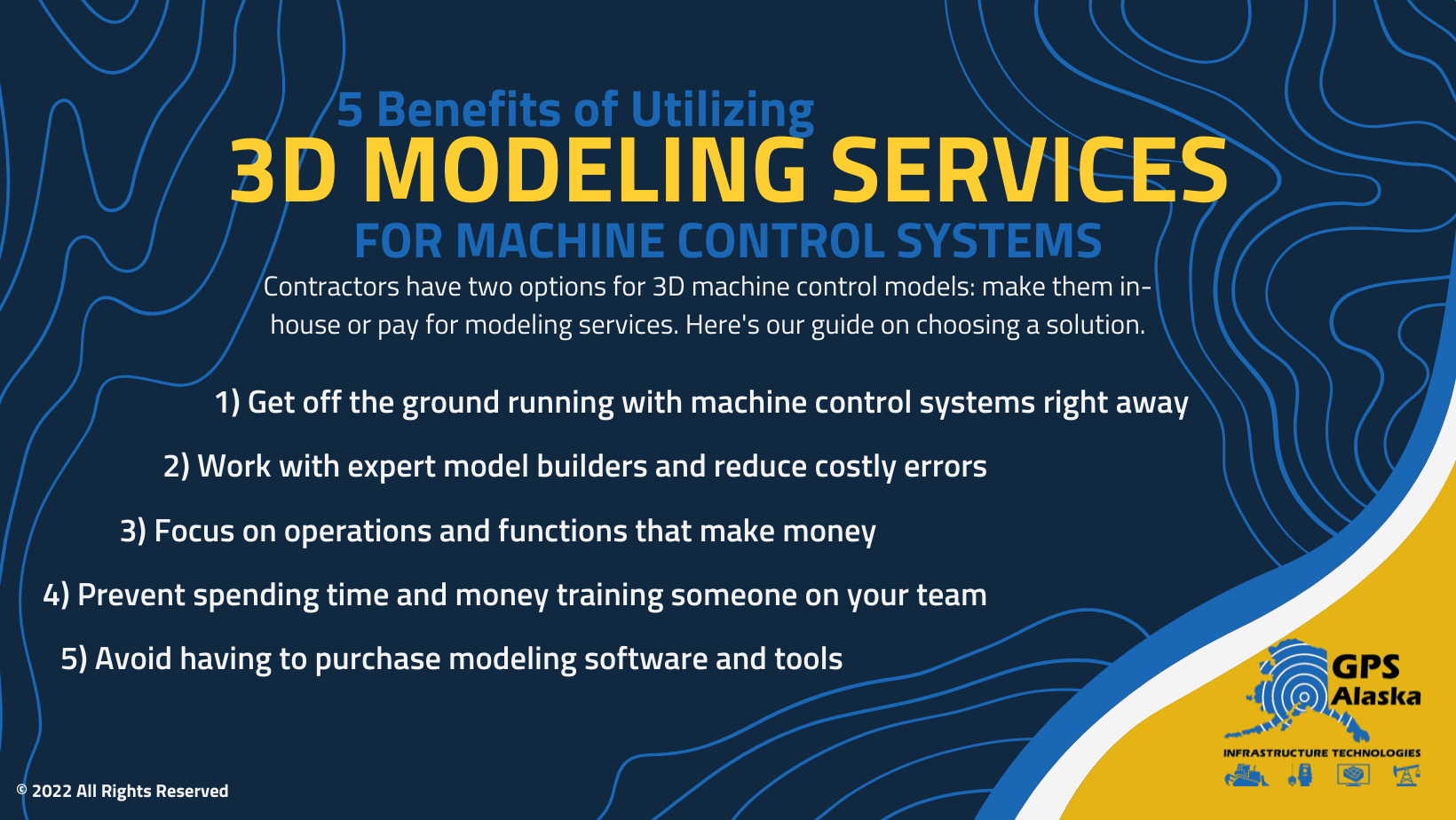

Trimble equipment control systems give a myriad of benefits to anyone that makes use of earthwork machinery and, at EarthCalc, we can give you with 3D apply for your device control-enable devices. Not exactly sure if machine control deserves the cost? Consider the following reasons you require to consider this choice.

Using general practitioner straightened with your 3D design files, these systems essentially assure that you will certainly remove or put the right amount of product at the building and construction website. On the majority of building and construction websites, rework is a typical and frustrating fact, yet with Trimble machine control, you can eliminate the requirement for rework.

Not known Facts About Sheroz Earthworks

Often, with Trimble maker control, you can remove excess tools at a specific job site. A work that could have required the use of 3 or four pieces of excavating equipment now could require just 2 items of devices to achieve the very same job in less time. This read this enables you to relocate your devices to one more job site and manage numerous tasks at one time.

Report this page